(+91) 9825026762 |

(+91) 9825026762 |  (+91) 9328026767 |

(+91) 9328026767 |  (+91) 9377637951

(+91) 9377637951

(+91) 9825026762 |

(+91) 9825026762 |  (+91) 9328026767 |

(+91) 9328026767 |  (+91) 9377637951

(+91) 9377637951

Raw material receipt, Physical Inspection, magnetic material Testing at our testing Lab to ensure the receipt of material as per order specification.

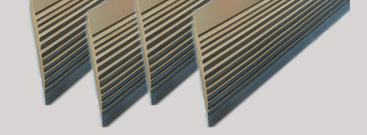

Choosing the right grade of material and make slitting plan to optimum utilization.

Slitting mother coils as per required sizes.

Choosing the right grade of material and slitting plan to optimum utilization.

Slitting mother coils as per sizes.

Shearing on Automatic CNC Cut to Length Line machine or manual shearing, Knotching, Hole punch and stress relief annealing (at 780°C-820°C) as per clients specs or design requirement.

Shearing on Automatic CNC Cut to Length Line machine or manual shearing, Knotching, Hole punch and stress relief annealing (at 780°C-820°C) as per clients specs or design requirement.

Fabrication of Automatic CNC Cut to Length line in conventional type or step lap type.

Fabrication of Automatic CNC Cut to Length line in conventional type or step lap type.

Final inspection for manufacturing tolerances as per IS 3024 as per clients requirement. Checking of core losses on finalised lamination issue test certificates.

Testing for mechanical dimensions and electrical values, to issue Test Certificates.

Packing for transportation

Packing for transportation